Product Information

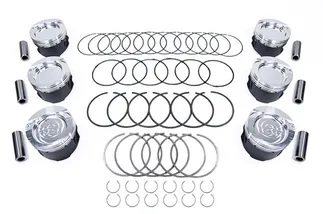

JE FSR Piston Set 2.0T FSI- 82.5mm 9.5:1

These are a complete set of JE pistons for all 2.0T FSI (timing belt driven) turbo engines. JE Pistons make for a stout reliable engine for daily driving, road racing, drag racing, or full out competition racing. Built to withstand serious performance punishment, JE forged pistons have been specifically designed and engineered for acceleration forces of more than 8000 G's and directional changes exceeding 200 times every second. Additionally, each forging is application specific minimizing weight and ensuring a reliable interaction with the rotating assembly. JE shelf pistons are available in a selection of bore sizes and compression ratios, if you do not see exactially what you are looking for, contact us for a custom piston quote. For use with 20mm wrist pin connecting rods such as Integrated Engineering h beam 144X20 or Integrated Engineering Tuscan I beam 144X20 connecting rods.

JE FSR Forged Pistons

JE's state of the art FSR forging. FSR forgings reduce mass and wear caused by friction without sacrificing strength. This is accomplished by using an asymmetrical skirt design instead of the traditional full-round skirt, also this reduces weight significantly. Designed specifically for boosted applications, FSR forgings utilize a larger, stronger skirt on the side of the piston which receives all the side loading during high pressure combustion process. The opposite skirt is smaller for light weight. FSR pistons still use a full width wrist pin and optimal large, wide pin bosses to carry the load of a turbocharged engine without wearing or ovaling out the pin bosses. In order to combat in cylinder noise commonly found in lightweight pistons, these feature an offset pin and keep very quiet in the bore. FSR pistons recieve strict quality control and 23 point post production inspection to ensure exact finish and tolerances in critical areas making the lightest, truely heavy duty piston on the market.

JE FSR design requires oil squirters to be modified or spaced out for clearance on some FSI blocks.

Features:

Includes JE wire locks, Pro Seal piston rings, and standard JE wrist pins

No dish deburring or preperation needed

Individually prepared inspection report of dimensional conformity

Each piston individually serialized for complete traceability

23-point post-production inspection conducted by certified personnel

Tighter tolerances on 14 critical areas of the piston

All critical surfaces machined in dedicated Critical Manufacturing Cell