Product Information

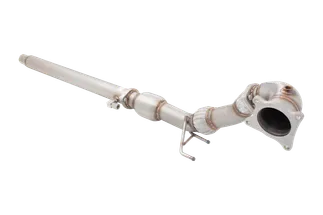

HPA 4.0T Downpipes for Audi (C7) S6, S7

Maximizing engine performance starts with engine heat management. Turbo charged applications generate extreme amount of surface heat at the turbo charger that radiates directly into the aluminum head reducing the engine ECU’s ability to advance ignition and fueling maps due to detonation. Besides strict global emissions standards resulting in restrictive catalytic converters being installed, oem engineers must factor global restrictions on minimum clearances for front impact crash test results when packaging and designing the factory turbo downpipes.

The average OEM 63mm downpipe diameter coupled with a restrictive catalytic converter and varying angles don't allow for ideal flow specifications and result in higher back pressure at the turbo forcing it to work harder and generate excessive heat.

HPA’s resulting 3” downpipe is a fabrication assembly designed around functionality and durability and proudly manufactured in Canada. Investment cast 304 stainless exhaust flanges and .063wall T304L stainless mandrel tubing is precision tig welded and Argon back purged for an ultra clean look on the exterior and a perfect clean weld on the interior.

S6/S7 downpipes come standard with our 300 cell metal cat, the same quality of cats used on all HPA twin turbo high performance vehicles.

Features:

- Improved throttle response

- Deeper Exhaust note

- High flow design

- Better heat management

- +35HP max power with consistent gains throughout the powerband

- Compatible wiith factory exhaust

- Perfect fitment

- Eliminates turbo lag

- Designed and assembled in-house

- 76mm Diameter

- Investment cast stainless 304 exhaust flanges

- T304L Stainless Steel

- 300 Cell High Flow Catalytic Converter

- Argon back-purged TIG Welds